MIG vs. TIG Welding: Which Is More Cost-Effective?

MIG vs. TIG Welding: Which Is More Cost-Effective?

In the United States, 75% of welding projects use MIG or TIG welding. TIG welding is often chosen for its precision and quality. At Chicago Welding Company, we offer expert advice on welding services. You can reach us at (224)678-8359 for professional guidance.

We will look at the differences between MIG and TIG welding. We'll focus on what makes TIG welding unique. Our aim is to give a detailed comparison of these two methods, highlighting their cost-effectiveness and the factors that influence their prices.

Understanding the Fundamentals of TIG Welding

At Chicago Welding Company, we stress the need for the right tools and skills in TIG welding. TIG welding is a precise method that needs special equipment and techniques.

It uses a tungsten electrode and an inert gas to shield the arc. Our team offers detailed advice on TIG welding best practices. This includes using tig welding equipment and tig welding tips for quality welds and safety. The tools for TIG welding include a TIG welder, tungsten electrodes, and inert gas cylinders.

Knowing the basics of TIG welding is key for quality welds and safety. We suggest investing in top-notch tig welding equipment and following expert tig welding tips for the best results.

Our team at Chicago Welding Company can guide you on TIG welding best practices. This includes using the right tig welding equipment and tig welding tips. By doing so, you can make high-quality welds and work safely.

MIG Welding Essentials and Operation Principles

MIG welding is a key process in many projects. It's important to know how it works and what it's good for. We can help you decide between MIG and TIG welding, looking at their uses and differences. MIG welding is fast and efficient, using a continuous wire and a shielding gas.

For MIG welding needs, talk to Chicago Welding Company. Our experts can guide you on MIG's benefits and uses in different fields. While MIG might not be as precise as TIG, it's great for quick work. We'll help you see if MIG is right for your project, weighing its pros and cons.

MIG welding feeds a wire electrode continuously, protected by a gas shield. This makes it fast and works well with many materials. Knowing how MIG welding works helps you choose the best option for your project, considering its uses and comparisons.

Initial Investment Comparison for Both Methods

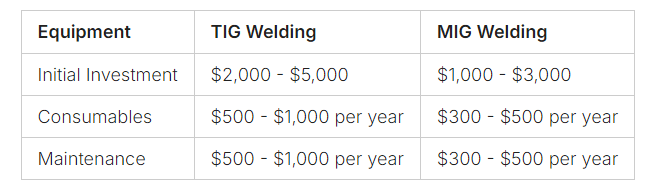

Choosing between TIG and MIG welding means looking at the upfront costs and long-term expenses. Chicago Welding Company suggests that TIG welding equipment is pricier than MIG. But, it's not just about the equipment cost. You also need to think about consumables, maintenance, and the learning curve for the operator.

Let's dive into the costs of both methods to help you decide. TIG welding offers high-quality welds and versatility, but it's more expensive. MIG welding is cheaper, but TIG welding has its own benefits.

Here's a look at the costs of TIG and MIG welding equipment:

In conclusion, the initial investment for TIG and MIG welding varies a lot. It depends on the equipment and brand you choose. By looking at all the costs, you can make a smart choice for your welding needs.

Operating Costs and Resource Requirements

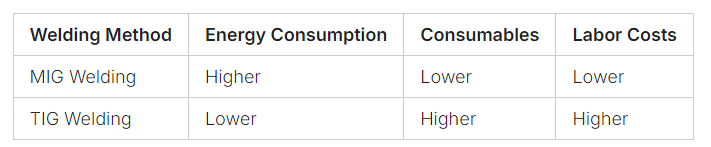

Choosing between MIG and TIG welding involves looking at costs and resources. At Chicago Welding Company, we suggest thinking about these for long-term savings. TIG welding needs more skill and time, which can raise labor costs. Yet, it can also mean better quality and less waste, saving money over time.

It's key to know the costs of both methods for planning and budgeting. Our team can guide you on making welding operations efficient and cost-effective. The tig welding techniques used affect energy use, materials, and labor costs. We can help you choose what's best for your needs.

The table below shows the main differences in costs and resources between MIG and TIG welding:

By looking at these factors and understanding tig welding, you can make a better choice. This choice should fit your welding needs and budget.

Material Compatibility and Application Range

Choosing the right welding method depends on the material and the weld quality needed. TIG and MIG welding have different uses based on material properties. TIG welding is great for thin materials like aluminum and copper, needing high precision.

MIG welding is better for thicker materials and is often used in steel welding. It's also good for high-volume production. For projects with different materials, experts like those at Chicago Welding Company can help choose the best method.

Our team ensures the chosen method meets the project's standards. TIG welding is used in many fields, from cars and planes to buildings and factories. Knowing the strengths of TIG and MIG welding helps us pick the right one for the job, leading to quality results and efficient work.

Material compatibility and application range are key when deciding between TIG and MIG welding. TIG is perfect for complex and precise welds. MIG is better for big projects and thicker materials.

By matching the welding method to the project's needs, we ensure the product is up to standard. With the right equipment and knowledge, TIG welding can produce high-quality results efficiently, making it a top choice for many applications.

Production Speed and Labor Efficiency Analysis

Welding speed and labor efficiency are key in any welding project. At Chicago Welding Company, we focus on these areas to boost productivity. Our team can improve your welding efficiency.

By looking at TIG and MIG welding, you can pick the best for your needs. TIG welding is great for precise, high-quality welds. But MIG welding is faster because of its continuous wire feed.

Our team will compare TIG and MIG welding for you. This helps you choose the right method for your project. We aim to help you save costs and work more efficiently.

Making the Right Choice for Your Welding Investment

Choosing between TIG and MIG welding depends on your project's needs. It also depends on the materials and your budget. Knowing the differences between these methods helps you make a smart choice.

TIG welding is great for projects needing a clean, high-quality finish. It's perfect for thin materials and designs where looks matter. MIG welding, on the other hand, is faster and more cost-effective for large projects.

Deciding between TIG and MIG welding requires careful thought. Our team at Chicago Welding Company can guide you. Call us at (224)678-8359 to talk about your project. We'll help you choose the best welding method for your needs.

© Created with systeme.io